In 2021 at Blue, we decided that we need to do more for the environment. Our Christmas message gave a brief explanation of what our goals for 2022 were. Over the last few months, Blue has been researching materials and their CO2 emissions in manufacturing so that we can use them to provide you with the CO2 emissions for the structure of your project so that you can get a better understanding of your project’s carbon footprint. To provide you with the figures there have been changes made to the drawings that we provide to you.

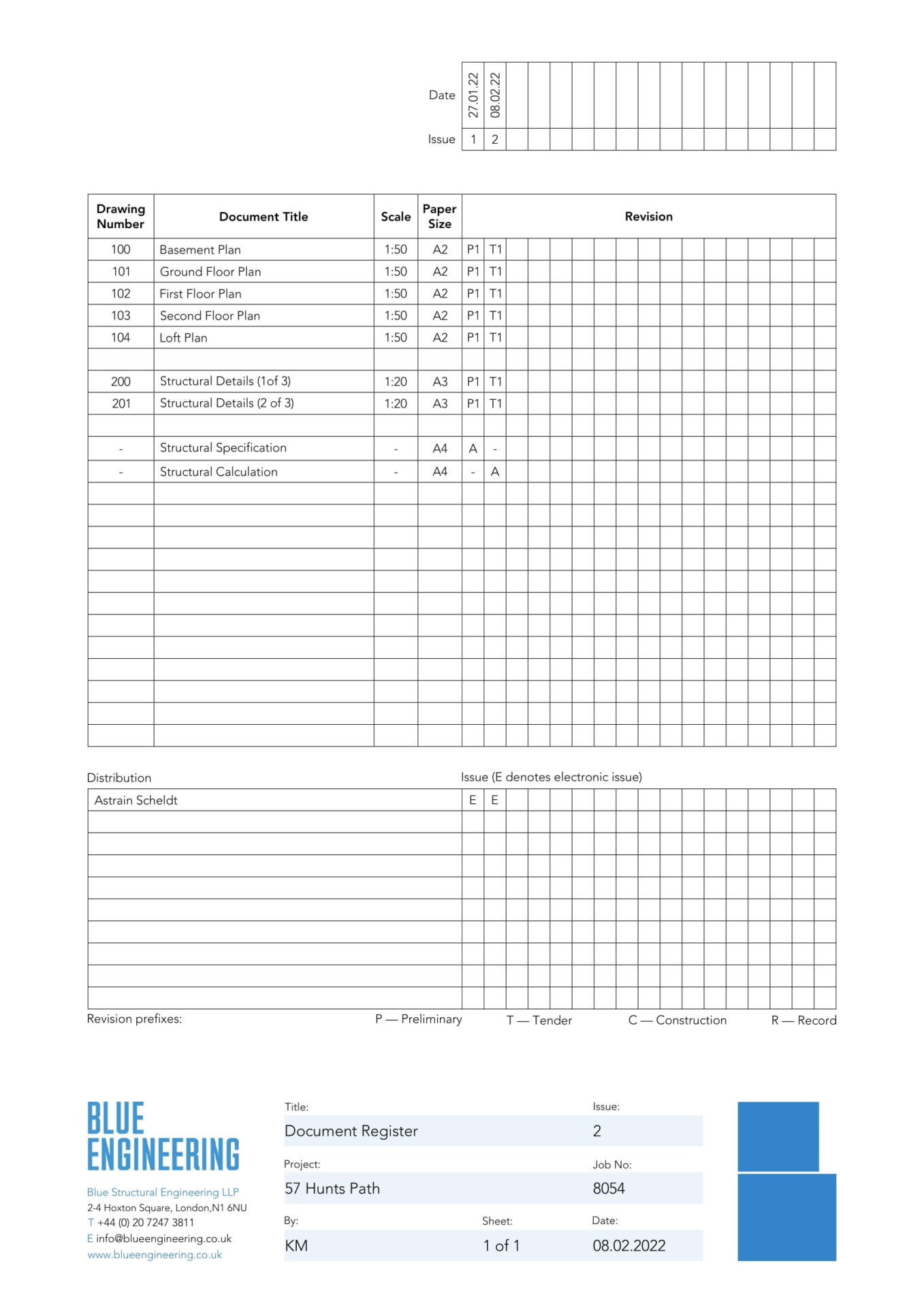

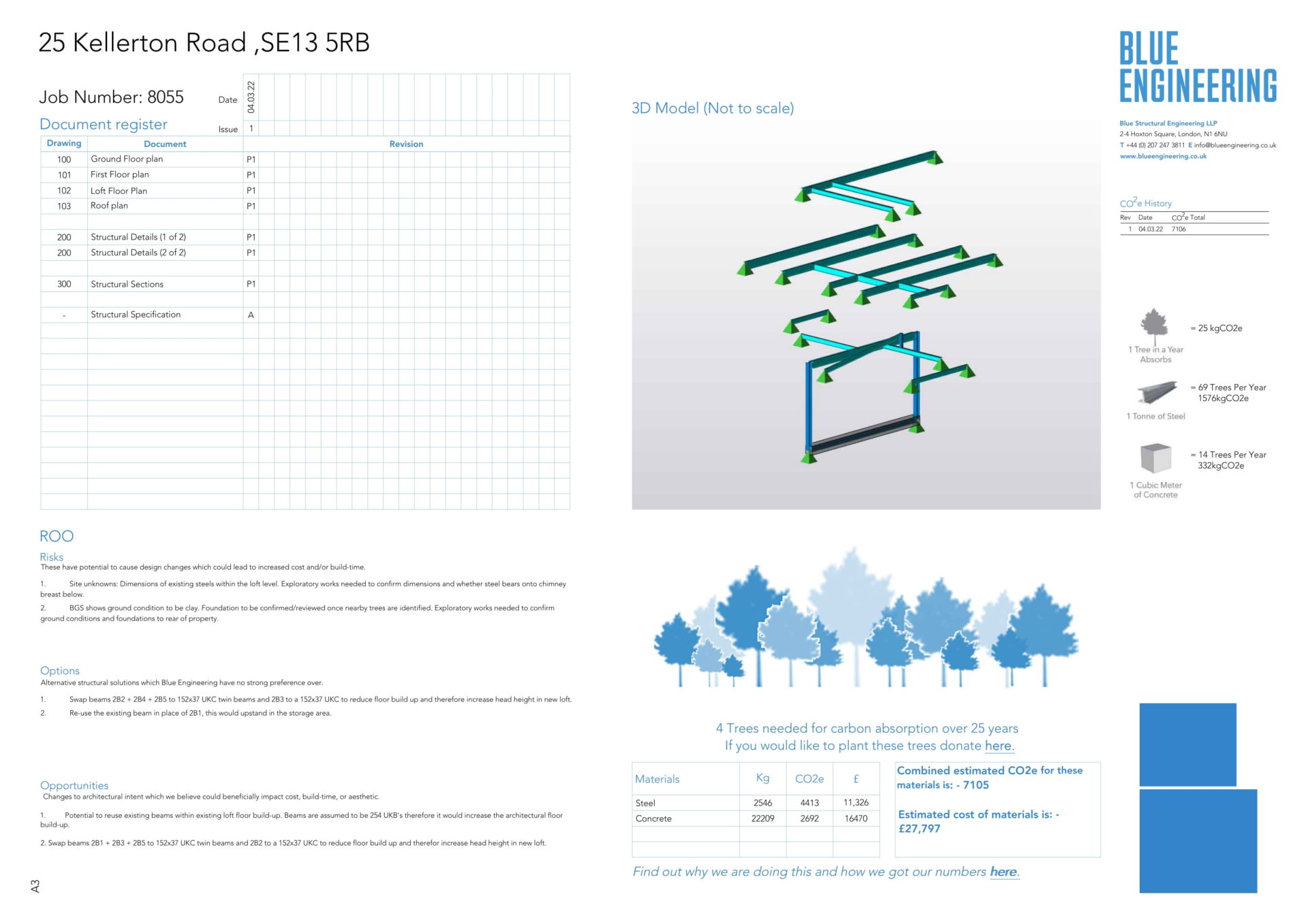

The first page of the drawings you receive will now have a combined document register and ROO (Risks, Options and Opportunities) so they sit on one A3 paper. The page will also include information on the CO2e produced by the materials used in your project.

What is a Document Register and ROO?

The document register is what we use to record all the drawings included in your package. It allows us to keep track of when each drawing was issued and when the revisions were made. The ROO is a document created at the start of a project that highlights any issues, or possibilities, that may come up during the project. It can bring up potential risks, such as ‘Depth of existing foundations unknown’, that our engineers will look out for on the site visit. It also points out any design options and opportunities that our structural engineers want to point out, for example, ‘A goalpost frame may help with wind stability.’

Our old document register:

What is CO2e?

CO2e stands for Carbon Dioxide Equivalent.

CO2e is used to describe greenhouse gases (GHG) in a common unit. Each GHG has a different Global Warming Potential (GWP), for example, CO2 has a GWP of 1 and Methane has a GWP of approximately 25. Using CO2e allows you to express other greenhouse gasses in the equivalent amount of CO2 that has the same global warming impact. This would mean for every tonne of Methane produced the equivalent would be 25 tons of CO2. This gives a better picture of the CO2e produced in the manufacturing of the materials for your project.

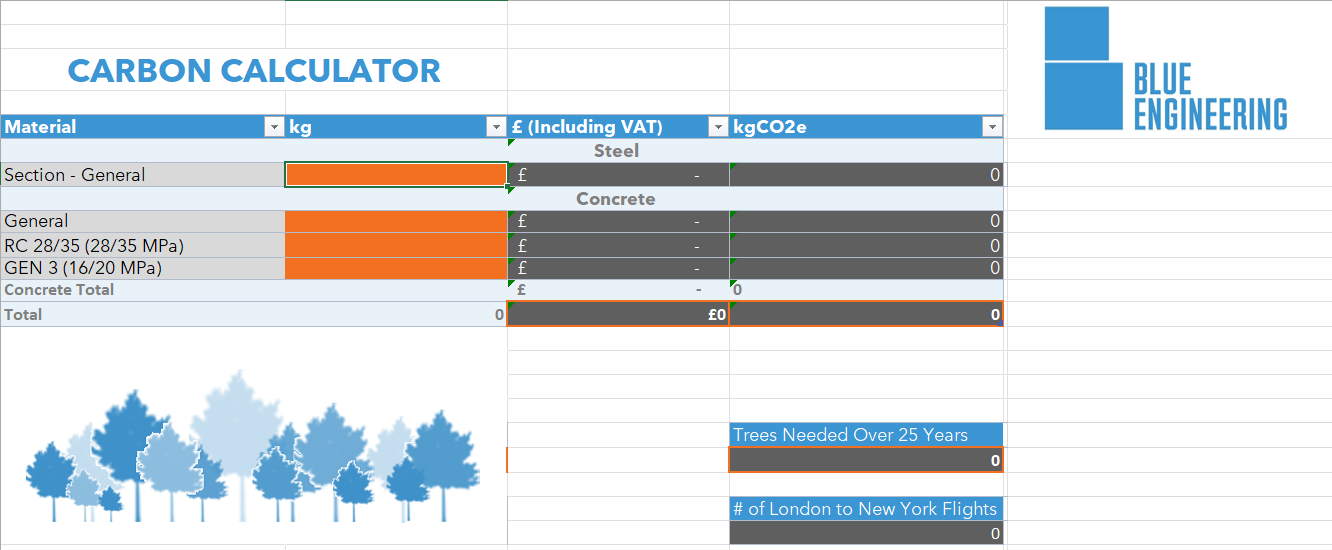

How are we calculating it?

Through our research, we have collected different resources that give us accurate CO2e numbers for the materials that we use. From tools produced by Highways England and databases, such as The Inventory of Carbon and Energy. We then collated all the relevant information into a spreadsheet that has become the Blue Carbon Calculator.

To produce our figures, we have had to make certain assumptions and allowances, this is to account for any information that we are unable to find. For steels, we have added an extra 3% of the total weight, this is to account for bolts and fixtures that we are unable to measure. We have also added an extra 10% to the overall CO2e emissions of the projects, this helps consider CO2e produced in transportation, assembly, and through waste. However, these numbers are not fixed, and we will continue to research and develop them to get an accurate picture as possible.

To give meaning to the numbers we will also express them through the equivalent number of trees. We have assumed a lifespan of 25 years for each project, meaning we will be looking at how much CO2e will be absorbed by trees during this lifetime. Going off the average amount of CO2 produced by a tree a year, 25kg, we calculate how many trees will be needed to absorb the CO2e produced by your project.

If you are interested in donating to plant trees, we recommend this charity here.

How are we costing the materials we specify?

By speaking to contractors we closely work with, we found the contractor’s fee for the main materials we specify – steel and concrete. The material cost of steel is priced at £3/kg whilst the material cost of concrete is priced at £120/m3 (5p/kg of concrete). Internally, these values are adjusted to include an extra 10% for bolts and fixtures, 20% for contractor overhead costs and profit, and 20% for VAT. This aims to give a true cost to the homeowner to help make more informed decisions. The final figures then become 7p/kg for concrete and £4.45 for steel.

The reason for including an indicative cost on our packages along with the material tonnage and CO2e values is to highlight trends between these figures. It is common to assume the more sustainably driven a project is, the more cost is incurred by the client. We are bold in sharing these figures to prove this isn’t always the case. Sustainable and efficient design means a reduction in material tonnage specified for the overall structure which also reduces the total cost of the project.

Why have we done this?

It encourages your engineers to think about how your project can have a positive impact on the environment. Highlighting the CO2e figures in your projects holds your engineer accountable for the design decisions made and encourages decisions that will not only save you on cost but with save on materials used, and thus on CO2e produced. Your project will start with a goal of reducing emissions and will have that in mind for each stage. It will provide your engineer with the information needed to compare different materials so they can choose the best one for your project and the environment.

What’s next?

This is just the start of the work we are doing this year. We will continue to develop our Carbon tool to carry on providing you with reliable information on your projects. We will also start to research the optimal materials and design methods so that we can produce innovative designs that help you and the environment.

Summary

All new projects will now include our new drawing register, with the ROO, CO2e information for projects, and cost estimates included. This gives you a better understanding of the impact your project has on the environment and helps our design teams reduce the impact of your project.

If you are interested in finding out more contact us here.