Written by Ruth Etioloja

Introduction

When making structural alterations to your home, the use of steelwork may be essential. At Blue, we endeavour to design efficiently and limit the steelwork we propose. Therefore, as you work with us, you may have queries regarding the steelwork we’ve specified. This article will explore common questions that we receive at Blue.

When existing load-bearing walls get demolished, steelwork may be specified to ensure the structure above the pre-existing wall is re-supported. Usually, this is the case when masonry elements, such as brickwork or blockwork, are demolished and need to be re-supported. The support could require; a single steel beam, a steel frame, which consists of steel beams and columns, or several steel beams. Two or more steel members fixed together require steel bolts and plates to form a connection. Steelwork may also provide fixings for glazing or balustrades, making sure the smaller details are accounted for.

Can steelwork be reduced?

There are several reasons to reduce steelwork in a build. Below two main reasons for reducing steelwork in construction are outlined:

Sustainability and Lowering Cost

Considering the impact your project has on the environment is responsible and could be a factor to reduce the steelwork on your project. For new builds or new extensions, the wall construction can be designed to allow for timber beams and posts, eliminating the need for steelwork. When carrying out internal or external alterations to an existing property, there may be no steelwork alternative.

The price of steelwork has increased exponentially since 2019. Many homeowners are looking to reduce steelwork to save on costs during refurbishments. It is possible, and it means there will be a reduction in the scope of works proposed; this is called value engineering. By reducing the number of walls demolished, less need to be re-supported. As opposed to steel, the use of timber is friendlier to the environment and cheaper.

Sometimes, it is not possible to reduce steelwork. Some steelwork is essential, even for timber structures, which is usually the case when considering the lateral stability of a property. Lateral stability means that the structure is strong enough to withstand natural forces, like wind, that could cause it to twist or bend. When designing according to modern building regulations, even a terraced property needs to have enough lateral stability to stand alone if the properties on either side are removed. This means it cannot move from side to side or sway; a steel frame may be necessary to help with this, especially if large sections of a spine wall or the rear façade have been removed. Large, glazed elements will also require steelwork for lateral stability.

Is your project underway? Send us your architect’s drawings with a note to request reduced steelwork, and we will review what can be done for you. Email us at info@blueengineering.co.uk

Can openings be created in steel beams?

Essential pipe utilities run throughout your property; their paths can clash with proposed steelwork. This isn’t a concern for every project, but when it is your structural engineer can collaborate with your contractor or architect to provide a design with an alternative route for the pipes.

If required, we can make openings in beams. These openings could be for pipes or electrical wires that cannot be re-routed. Openings in steelwork can be made for aesthetic purposes also. If steelwork is going to be exposed, then different shapes can be designed to create a feature in a room, or throughout the property. At Blue, our engineers would do this at our preliminary or tender stage, as creating openings in a steel beam will reduce its capacity. The beam specification may need to change to allow for the openings. Blue aims to reduce abortive work or additional steelwork and design costs that will be needed. Therefore, raising this issue before your engineer’s design is finished, mitigates the risk.

Do you need an alternative steelwork design for your project? Call us on 020 7247 3811, to find out how we can help you. Or you can email us at info@blueengineering.co.uk

How much does steekwork cost?

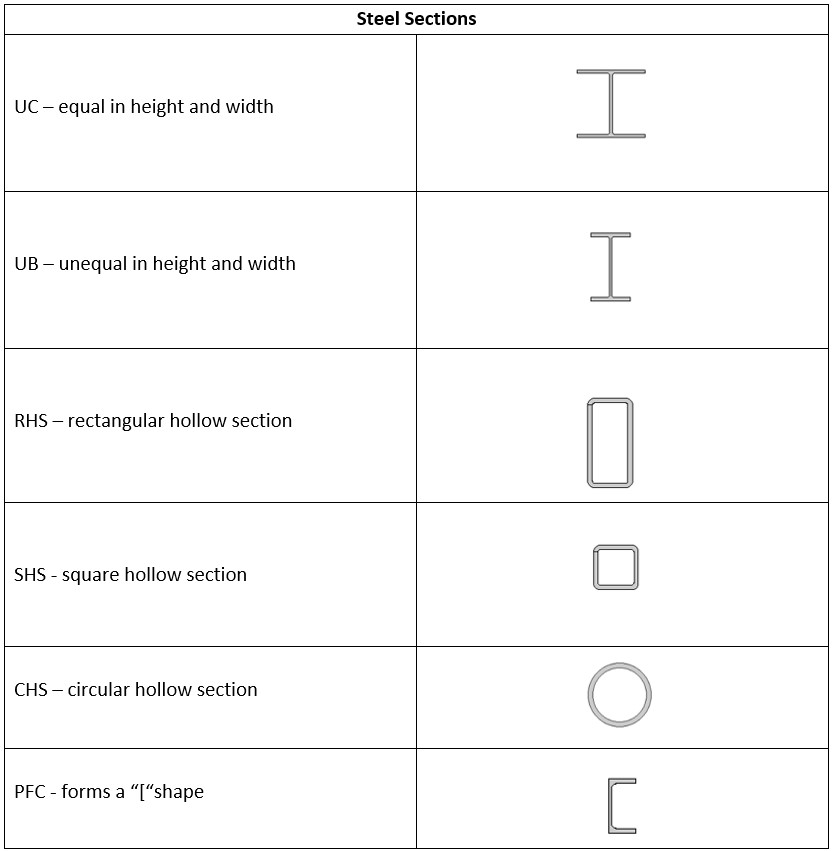

Steelwork costs differ between suppliers, but the guiding price is £5 per kg. Steelwork costs differ in price depending on their size. Please see below for an example of different steel sections:

Pricing example: a standard steelwork size is a 152 x 152 x 37 UC beam. The beam depth and width is 152mm, with a weight of 37kg/m2. Therefore, if you order a three-metre long 152 x 152 x 37 UC, you will be charged approximately £185 per metre; for three metres, this will be £555.

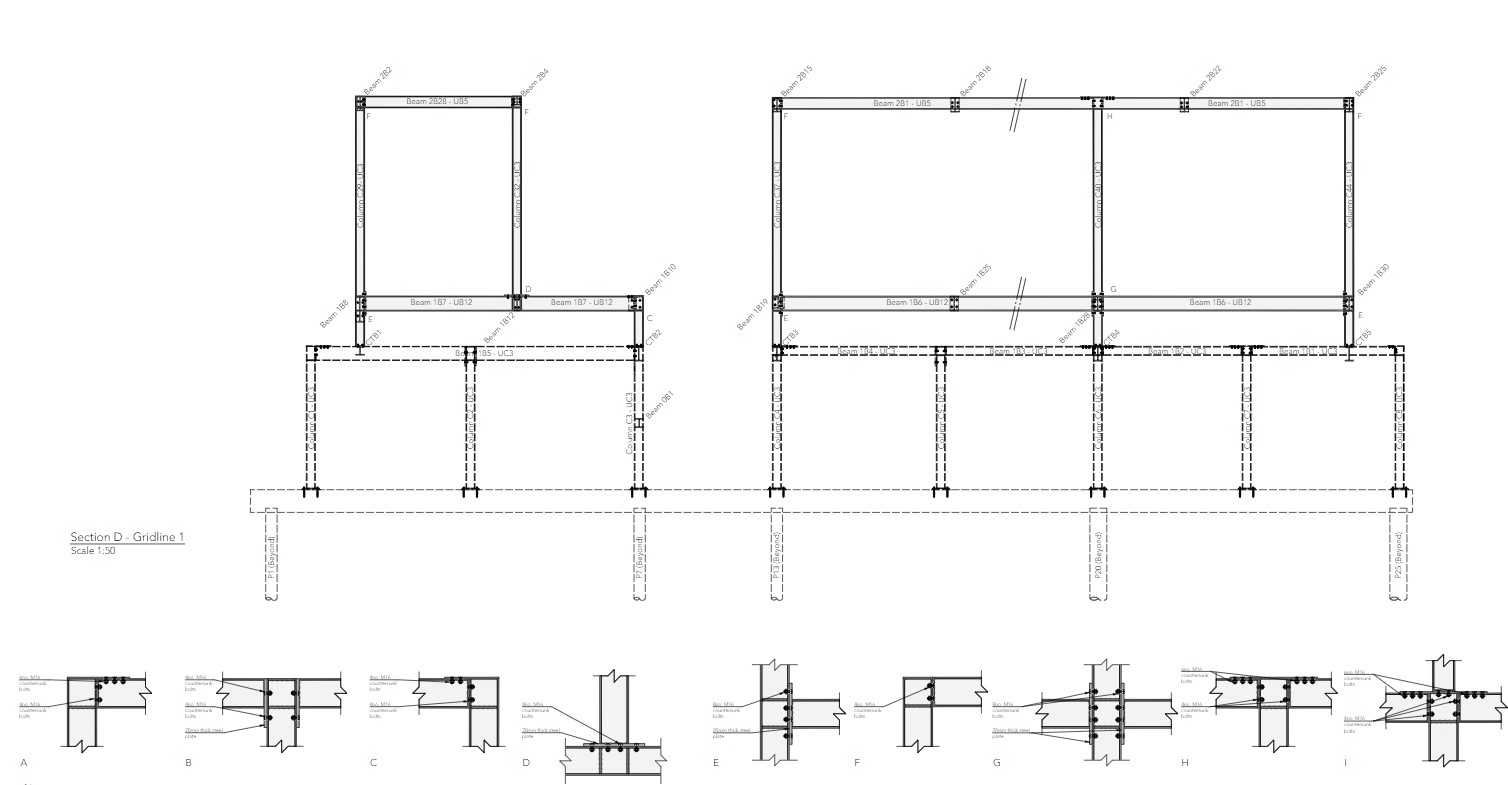

Steelwork details that Blue Engineering provides

As part of Blue’s preliminary and tender packages, you will receive steelwork details that range from bespoke connections for aesthetic features to larger steel frame sections.

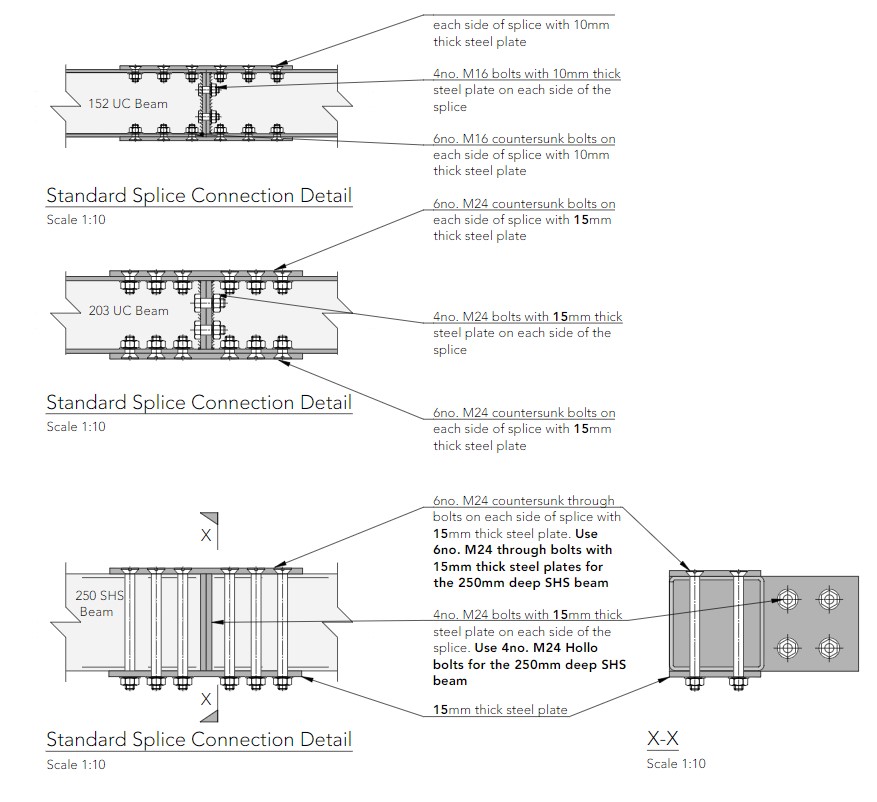

Steelwork connection details

During the construction process, unexpected challenges may arise, and Blue’s engineers will be on hand to provide indicative sketches and guidance to your contractor to ensure structural stability.

The drawings you receive from us, are based on the survey taken by your architect, which provides us with the dimensions we use. Therefore, we generally don’t provide steelwork fabrication details for cranked beams. The dimensions and levels need to be measured and confirmed on site. A cranked beam is a beam that changes in level; the steelwork fabricator must investigate these levels on site. All steelwork connections are highlighted on our plans, some are written up in notes, and others are detailed further in the package for clarity.

Email us at info@blueengineering.co.uk with your architect’s drawings, to receive a quote on the structural design of your project.

Tips for your project

– Look through the sketch scheme provided in detail. The scheme will provide you with a clear picture of the steelwork proposed, you can have a productive discussion, with us, about reducing it or tweaking our design. This will save time later in the process and provide a more cohesive package at the preliminary stage.

– Smaller openings require lighter sections of steelwork, or even off the shelf lintel products, which can reduce the cost of materials. Lintels are small steel or steel-reinforced concrete beams that can bridge openings externally and internally. They have various shapes and sizes to suit different wall constructions, with various specifications and manufacturers. A structural engineer will need to check the specifications of a specified or preferred lintel to ensure its capacity is adequate.

– If any detail is unclear during construction, we can quickly and indicatively sketch the connection for clarity or approve steelwork fabrication drawings for peace of mind.

In Summary

It is possible to reduce steelwork in most builds however, this may affect the original design. Value engineering can help save costs and the environment; it’s a great factor to consider at the beginning of a project. Openings can be created in beams, but this may mean the size of the beam increases due to a reduced capacity, so alternatives can be found if this isn’t an aesthetic design element.

Blue Engineering produces a variety of essential details; some projects need more than others, and you can always contact us to clarify any designs. Please feel free to contact us throughout your renovation, we’ll be on hand to answer the questions you may have.

If you are looking for a structural engineer to design for your project, call us on 020 7247 3811 or email us at info@blueengineering.co.uk We can advise you on how to reduce steelwork usage and give you a quote.