Introduction

In this article, we will be exploring what stressed skin floors are, how they are designed and when they can be used.

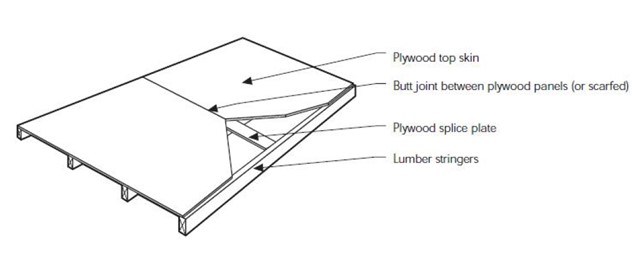

Stressed skin panels consist of an efficient timber cross-section created by connecting timber sheets, forming the skins on the top and/or bottom face of solid timber joists. Usually, the webs are formed from rectangular-shaped timber joists whereas the sheets consist of plywood.

When two or more separated elements are connected to work together as one structural element, we form a composite section.

Composite timber sections are assembled by glueing or screwing the timber elements down to form a single stiffer unit and consequently, the values of the single elements alone in terms of deflection and strength will improve:

– Deflection will be reduced.

– The strength will increase.

As a result, the structure is working more efficiently, and the overall structural build-up can also be reduced.

Conventional timber joists vs stressed skin floor

Conventional Timber Floor

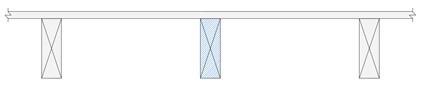

Timber joists are widely used in residential refurbishments for their lightweight, low cost, simplicity, and low impact on the environment. The design is to be carried out in compliance with the EuroCodes, which are a series of European Technical Standards that provide an approved and safe approach to the structural design of buildings.

The design of a timber floor is often governed by deflections and vibration, timber floors require deep sections that will mainly impact the often tight head height. As an example, on a conventional loft conversion, a shallower floor gives the opportunity to use a larger area as habitable space. Cleverly using the ply that is usually installed over the joists as a structural member, will improve the overall stiffness and strength of the timber floor. Stress skin behaviour can also be used as a retrofit, strengthening when floors are found to be bouncy.

How to efficiently use plywood sheeting over the timber joists

New timber joist floors and roofs have a layer of plywood sheeting over them to enable finishes to be laid on their surfaces. The ply sheet is not mechanically fixed to the joists and therefore, this cannot be taken into account when designing the timber elements as the ply can slide over the joists and the composite section is not formed.

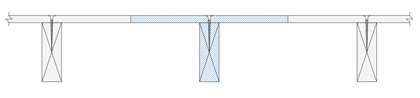

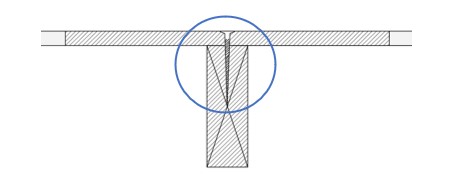

When a sheet of ply is fixed on the top or bottom of a timber joist, we effectively create a T-shape beam with a large mass, away from the centroid; thus creating a stiffened floor and ultimately, more efficient structural depths.

I = Flexional stiffness. This is the term used when referring to measuring the stiffness of the floor. Therefore, increasing the I value will reduce the overall deflection of the floor. As an example, 18mm ply fixed to 150x50mm joists at 400mm centres approximately provides a 100% increase in flexional stiffness.

How does stressed skin flooring work?

To enable this composite action between the conventional, rectangular-shaped joist and the plywood layer, we need to undertake a key design check of what is technically called “rolling shear,” which is the force transferred through the fixings, along the connection line between the joists and sheets.

This guarantees that the connection between the elements, provided by the glue and screws, is sufficient to consider the T-section as one full section.

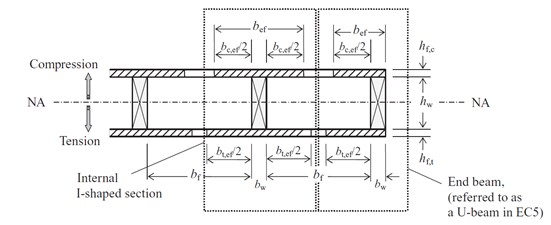

Ply sheets can also be installed on both faces. This will increase the stiffness even more. In fact, the system will act as a series of built-up I-beams where the plywood skins will take most of the bending stresses providing a pull-push force and the joist will take shear stresses.

Does your floor feel bouncy?

Sometimes stressed skin is used on existing floors as a strengthening aid against vibration issues when a floor is found to be bouncy or not adequately stiff. The layer of ply can also be installed on the bottom face, and it will improve the stiffness of an existing floor without having to remove all the floor finishes or upgrade the floor with extensive remedial works.

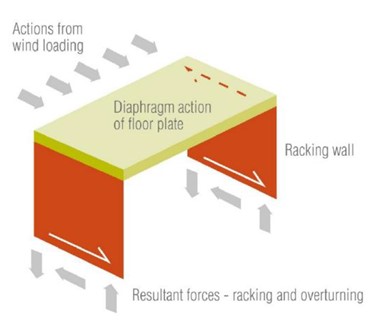

Use of stressed skin floors for diaphragm action

Stressed skin floors can also be implemented when lateral loads need to be transferred across the floor plate into the walls or frame, and then the ground. The inherent stiffness, high tension properties of plywood, positively fixed to the solid timber floor joists with high compression characteristics, will form a rigid diaphragm. This enables the transfer of load across the floor plate and into the bracing elements.

Conclusion

In most situations when the size of the loft boundary conditions are standard, and there are no critical head-height constraints, conventional timber joists are the best option. Also, when lateral stability can be achieved by using walls or frames, stressed skin floor may not be needed.

Stressed skin panels are primarily used as bending members in floors and roofs and by cleverly designing the connection between the timber elements it is possible to form a more efficient, stiffer and stronger composite section.

Stressed skin floors and roofs maximise the efficiency of the timber sections resulting in a thinner structural build-up which is often a goal on loft conversion when the head height is critical.

Stressed skin is also suitable for remedial work when existing timber floors need to be strengthened.

Has your loft conversion been approved? Do you need a structural engineer to work with? Send your architect’s drawings to info@blueengineering.co.uk.