Climate change and the environment are huge concerns in our planet’s future. It is a topic that cannot be avoided any longer. Longevity is one of Blue Engineering’s core values, we recognize that “we will get the greatest results if we plan for the long term”. This value goes hand in hand with sustainability; to have a viable future, we must preserve the environment. Climate change and a contaminated environment are threats to human health, biodiversity, and a good living condition for the future. Prioritizing longevity is synonymous to prioritizing sustainability.

It is important to realize what each person can do to alleviate their impact on the planet. Working in the building and construction industry gives Blue the opportunity to help the environment by reducing the harmful emissions in the world. In 2020, the building and construction industry accounted for 37% of all energy related emissions. This shows that there is a lot of work to be done and many areas of improvement in the industry, which begs the following question: How can engineers at Blue make a difference?

According to Bryn Davidson, a Canadian architect focused on designing net-positive buildings, change primarily comes from choosing the right projects. One of the key aspects in renovation is to look at properties that are producing the most emissions and make them more energy efficient. At Blue, this is manifested as working with architects and clients who prioritize sustainability. Prompted by the incentive or our engineers, the company is building its reputation for sustainable building and looking to attract more clients with this aligned interest.

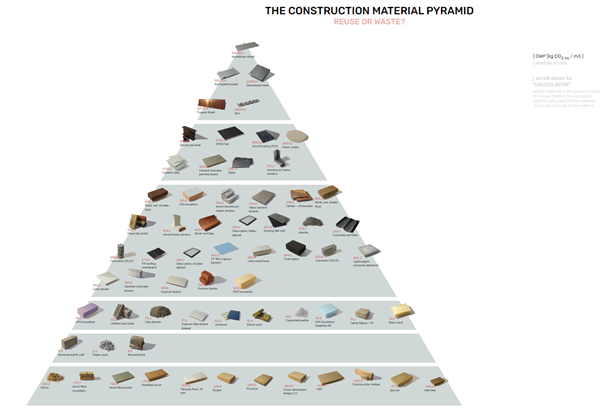

From a more technical perspective, engineers make an impact through the solutions advised to clients. More specifically, the materials recommended. The sustainability of a material depends on different factors, such as recyclability, efficiency, and production. A useful tool used to visualise this is the “Construction Material Pyramid” which ranks materials based on their carbon dioxide (CO2) production (Figure 2). This is a one-stop comprehensive tool that allows engineers to quantitatively understand the impact of each material. One of the key aspects of this pyramid is that the material ranking changes based on their application. The pyramid looks different when CO2 production of each material is categorized against mass rather than volume. This difference demonstrates that not everything is black and white. It is important to account for different factors while considering the sustainability of a material. factors such as ozone depletion, acidification potential, and eutrophication potential also contribute to the sustainability of the material. Therefore, the context in which the material will be applied is evaluated by our engineers to have a wholistic view of the environmental impacts of a project and find the best solution for said application.

Steel is one of the most used construction materials. From a simple google search, it appears to be very sustainable as it is easily recyclable without the need to use more raw material. In fact, it is the most readily recycled material in the world. However, the fact that steel is recyclable does not mean it makes the industry more sustainable. The recycled scraps are usually made into smaller steel products, which are not used in construction. In fact, two-thirds of the steel used in the UK still come from primary production, which is a very carbon intensive process. At the moment, the steel-making industry amounts to around 8% of all global carbon emissions. This industry needs to focus on using renewable energy sources and recycling to improve their sustainability, but these steps require systematic changes that take a long time. Meanwhile, Timber is organic, non-toxic and naturally renewable. On average, primary material production of steel produces 2.21 to 2.44 kg of CO2 for every kilogram of steel produced, while timber produces 0.348 to 0.384 kg of CO2 for every kilogram of timber. Timber produces about 85% less CO2 for each kilogram produced compared to steel, making it a significantly more sustainable alternative to steel.

The potential of timber is highlighted by the world’s largest timber-frame construction in Norway, the Mjøstårnet Building (Figure 4). This is an 18-storey building of nearly 122,000 square feet. The structure is defying common concerns of using wood in construction such as fire safety and strength. To prevent against fires, the timber was surface treated to make it incombustible. Additionally, large scale columns and trusses were used so all horizontal and vertical loads are completely supported by the timber structure. Using timber to construct such a large building shows the material’s potential to be a sustainable alternative to steel which should be more readily implemented. This project has inspired multiple proposals of other large timber frame structures such as a 70-floor wood frame tower in Tokyo. Likewise, this example helps inspire engineers at Blue to implement more timber in their designs.

Due to regulatory restrictions in the United Kingdom, there are projects where timber cannot be used to replace steel. This means that engineers can make the most of opportunities where they can design using timber without restrictions such as new builds and detached structures. Another challenge of working with timber instead of steel is that steel is stronger than timber, so larger amounts of timber are needed compared to steel to support the same structure. However, these larger structural details can be incorporated into the architectural and interior design details of the project. Kengo Kuma, a world renown Japanese architect, is an exceptional example of this practice. He is known for embracing nature and social responsibility in his designs, which often feature timber details (Figure 5). Our engineers take advantage of opportunities to work with architects who are open to incorporating timber into their designs.

Finally, engineers at Blue make it a priority to stay informed on new sustainable solutions in the building and construction industry. Having innovation as one of the company’s core values shows our willingness to look for new, better, and more sustainable solutions. This is specially manifested in Blue’s approach to work where engineers make an effort to keep up with the latest innovations, stay conscious about their environmental impact, and initiate change.

As sustainable solutions become more available, sustainable constructions will become the standard. Presently, the industry is still at a stagnant point where the standard construction practices are not environmentally positive. Now, the construction industry must make a big step forward in the direction of creating net carbon positive projects and a new standard for construction and renovations. Once a more environmentally friendly standard is set, it will be easier to follow along. Blue engineering seeks to be an innovator and pioneer in this area.

Going forward, our engineers are taking the responsibility of making the building and construction industry more sustainable. The three main actions our engineers are following to make

Blue a more sustainable company and maintain the company’s focus on longevity and innovation are the following:

- Be conscious of the effects of different materials and understand the industry from a wider scope from material production to construction.

- Build Blue’s reputation as an environmentally conscious engineering company to attract more clients who prioritize sustainable building.

- Stay informed about new sustainable solutions and be open minded to implementing them.